ʻAʻole hiki ke nele ka leka uila

ʻAʻole hiki ke nele ka ʻōlelo huna

Hapa ka hoʻopono leka uila

ʻAʻole hiki ke nele ka leka uila

Loaʻa ka leka uila

6-20 mau huapalapala (nā leka me nā helu wale nō)

ʻAʻole kūlike ka ʻōlelo huna

Hapa ka hoʻopono leka uila

ʻAʻole hiki ke nele ka leka uila

ʻAʻohe leka uila

6-20 mau huapalapala (nā leka me nā helu wale nō)

ʻAʻole kūlike ka ʻōlelo huna

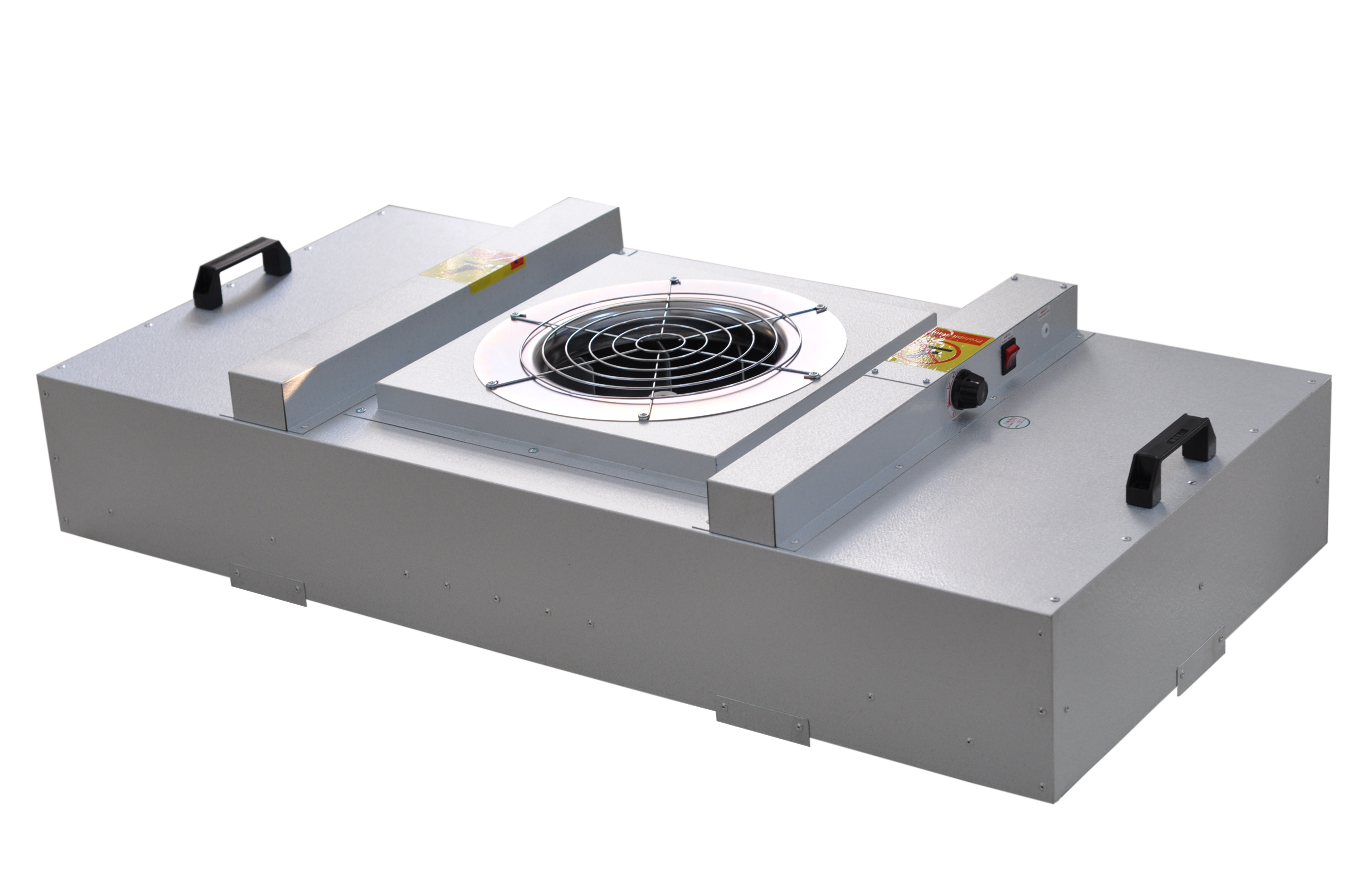

Static eliniculation ffu (fat filter unit)

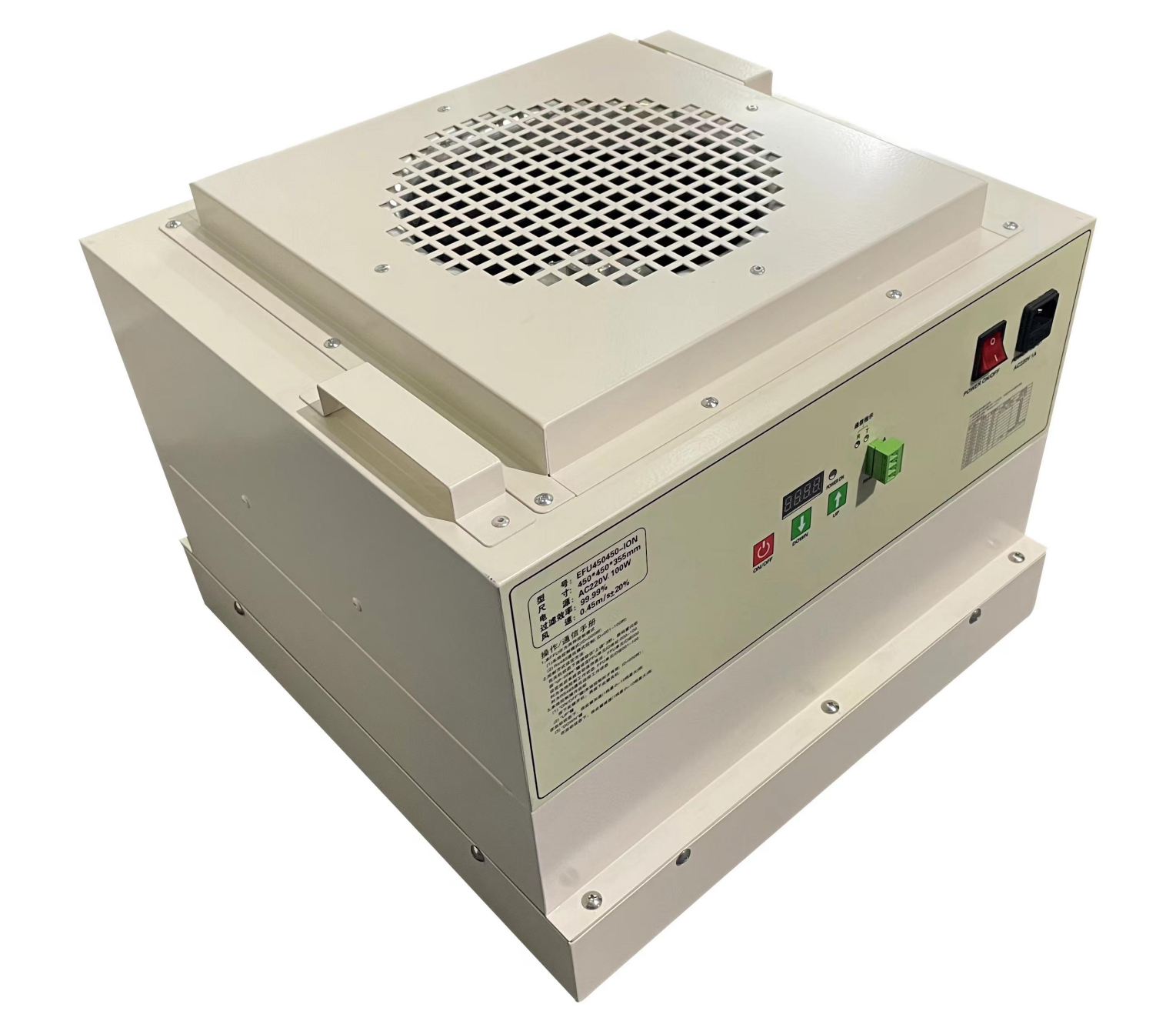

Ka hoʻolaunaʻana i ka EMIGNXIN Static Elimina FFU, kahi hopena innvative e hoʻopiliʻia e haʻi i nā pilikia o ka uila static i loko o nā wahi pili. Hoʻohuiʻia kēia hui kānana holomua holomua i nāʻoihana mokulele e pono ai e hōʻoia i kahiʻenehana elimit kūpono. ʻO nā hiʻohiʻona nui a me nā pōmaikaʻi: 1. I kaʻenehanaʻo Storic Elimen: I ka wā mua o kāna hana e hoʻonui ai i nā uku static. Hoʻopau kēia i ka hopena o ka hopena o ka electrostatic (esd), pale i nā mea uila uila, nā mea kūpono, a me nā mea hanaʻole. E hoʻonui nō hoʻi i ka palekana palekana ma o ka hōʻemiʻana i ka hopena o ka hikiʻole o nā meaʻole a iʻole ke ahi. 2.ʻO ka loaʻaʻana o ka hana kiʻekiʻe: pono me kahi hepa kiʻekiʻe kiʻekiʻe Hoʻopili kēia iā Dust, pollen, nā maʻi, nā maʻi, a me nā mea nui, e hōʻoia ana i kahiʻenehana maʻemaʻe a me ke olakino. ʻO ka mea i hāʻawiʻia i ka'ōnaehana kiʻekiʻe kiʻekiʻe loa i hāʻawiʻia e hoʻomaikaʻi maikaʻi aku i ke olakino maikaʻi, e hoʻonui i ka huahana, a hoʻomaikaʻi i ka maikaʻi huahana. 3 E hoʻopau nui ka mana o EC ʻO kēia hiʻohiʻona eco-maikaʻiʻole e loaʻa wale i kāu laina lalo akā ua hāʻawi pū i kahi kūlana Green. 4. Ka hana pololei a me ka hanaʻana: Hāʻawi ka waihona i ka hoʻokele pololei ma luna o ka wikiwiki o ka Fan Speed e like me nā koi kūpono. Hōʻike kēia i ka hana o ka hana a me ka noho mālie a me nā hana maʻamau e kūpono i nā noi likeʻole. Eia kekahi,ʻo ka papa inoa hoʻohui a me ke kuʻekuʻe wāwae e hana maʻalahi e hoʻohui i nā'ōnaehana HVAC a iʻole nā hoʻonohonohoʻana, Hoʻohuiʻia. 5 ʻO kāna kūkulu kūkulu ikaika e kū'ē ai i nā koi e pili ana i nā koi o kēlā me kēia lā i ka hoʻohanaʻana i kaʻoihana,ʻo kaʻoihanaʻepekema. Hoʻolālāʻia ka waeʻana no ka lōʻihi lōʻihi a me ka hilinaʻi, e hōʻemi ana i ka pono no nā mea hou a hoʻoponopono hou paha. 6.ʻO ka hana hoʻohana-hoʻohana a me ka mālamaʻana: intuitive consrols a me nā'ōnaehana mālama i ka hana maʻalahi a me ka mālama. Hiki i nā mea hoʻohana ke hoʻoponopono maʻalahi i ka wikiwiki o ka wikiwiki ʻO ka hoʻolālā haʻahaʻa haʻahaʻa e hōʻoia i nā hana maʻamau e wikiwiki wikiwiki a me ka hoʻoikaikaʻana,ʻoi aku ka hoʻonui houʻana i nā uku hana hana. Hopena ʻO kānaʻenehana SECECIOND SPECIC eligination, kiʻekiʻe loa i ka hana, ka hana ikaika-ikaika, ka mana kūpono, a me ka mea hoʻohana.

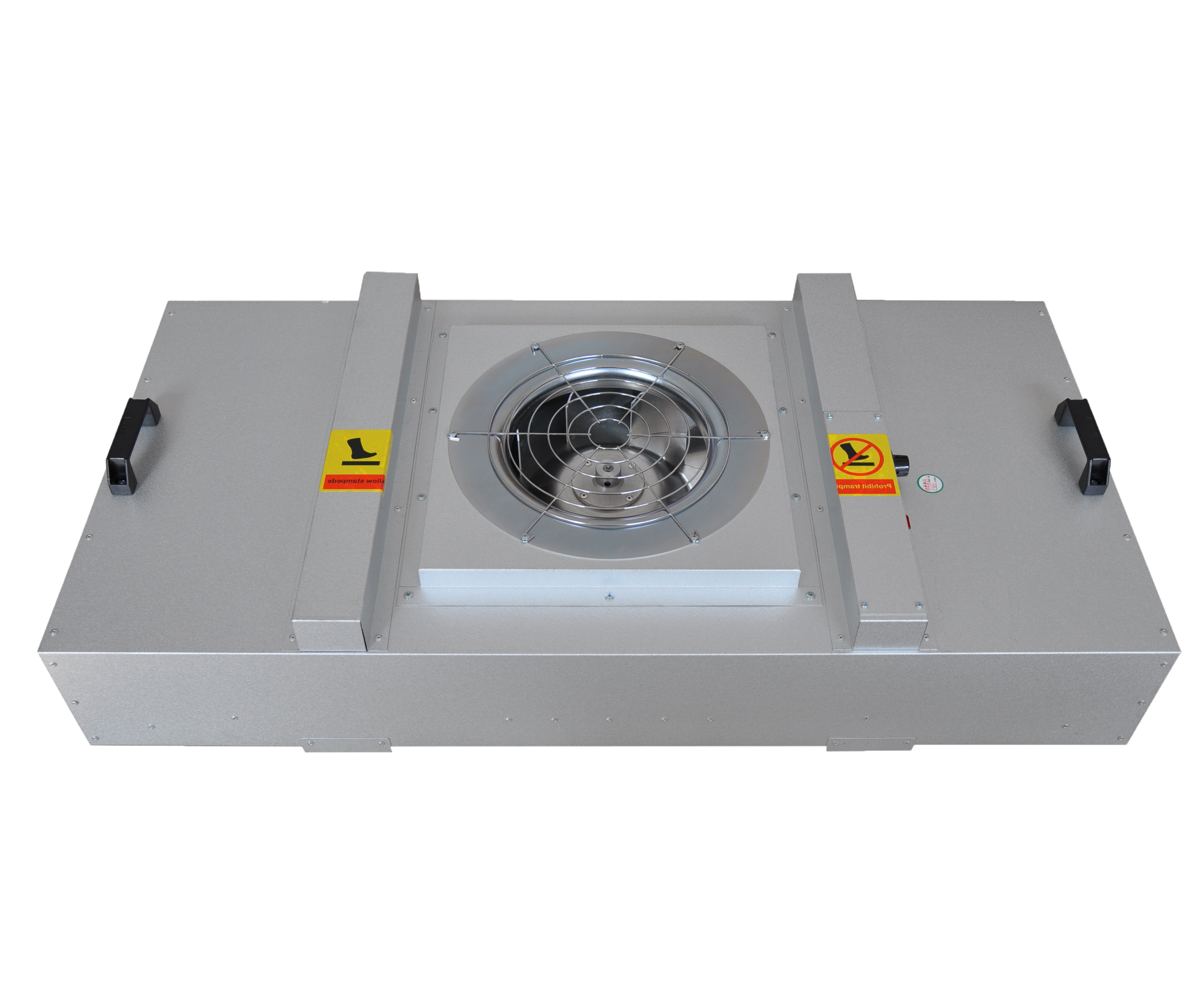

The Deshengxin Static Elimination FFU is a comprehensive air purification and electrostatic control solution designed to create an optimal work environment in cleanrooms, electronics manufacturing facilities, laboratories, hospitals, and other sensitive areas. This state-of-the-art fan filter unit combines the efficiency of high-performance air filtration with the precision of advanced static elimination technology, ensuring unparalleled air quality and electrostatic neutrality.

Product Overview:

1. Core Functionality:

Static Elimination: Integrated with high-performance static eliminators, the Deshengxin Static Elimination FFU continuously neutralizes static charges in the air and on surfaces. This prevents electrostatic discharge (ESD) events that can damage electronic components, disturb delicate processes, or pose a safety hazard.

Air Filtration: Equipped with a HEPA filter or optional ULPA (Ultra-Low Penetration Air) filter, the unit efficiently removes airborne particles down to 0.12 microns in size. This includes dust, smoke, pollen, bacteria, viruses, and other contaminants, maintaining a clean and healthy atmosphere.

2. Energy Efficiency and Performance:

EC Motor: Driven by an energy-efficient EC (Electronically Commutated) motor, the FFU provides strong airflow while consuming minimal electricity. This not only reduces operating costs but also aligns with environmental sustainability goals.

Adjustable Speed Control: Precise control over fan speed allows users to customize airflow to suit specific requirements. This ensures optimal performance in various applications while maintaining a low noise level.

3. Design and Durability:

Modular Design: The unit's modular construction facilitates easy installation, maintenance, and replacement of components. Its compact size makes it ideal for both new installations and retrofitting existing systems.

Durable Materials: Manufactured using high-quality materials, the Deshengxin Static Elimination FFU is built to withstand the rigors of industrial and commercial use. Its long service life minimizes downtime and maintenance costs.

4. Monitoring and Maintenance:

User-Friendly Interface: An intuitive control panel provides real-time monitoring of fan speed, filter status, and other critical parameters. This simplifies operation and maintenance, ensuring optimal performance at all times.

Maintenance Alerts: The unit automatically alerts users when filters need to be replaced or other maintenance tasks are required. This proactive approach prevents unexpected downtime and ensures continuous operation.

5. Customization Options:

Filter Options: Users can choose between HEPA and ULPA filters based on their specific requirements for particle removal efficiency.

Static Elimination Technology: The static eliminators can be customized to suit the specific electrostatic challenges faced by individual applications.

Accessories: A range of accessories, such as mounting brackets, remote controllers, and air diffusers, are available to enhance the unit's performance and ease of use.

6. Safety and Compliance:

Compliance: The Deshengxin Static Elimination FFU meets or exceeds international standards for air quality, electrostatic control, and safety, ensuring peace of mind for users.

Safety Features: The unit is designed with safety in mind, incorporating features such as overheat protection and electrical insulation to prevent accidents.

In summary, the Deshengxin Static Elimination FFU is a versatile and reliable solution for maintaining a clean, healthy, and electrostatically neutral work environment. Its combination of advanced static elimination technology, high-performance filtration, energy efficiency, durability, and customization options make it an ideal choice for a wide range of applications where precision, safety, and productivity are essential.

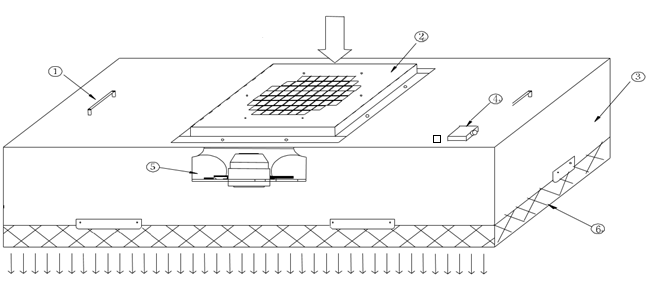

FFU Assembly diagram

|

1 |

|

5 |

Motor |

|

2 |

|

6 |

HEPA filter |

|

3 |

|

|

|

|

4 |

|

|

|

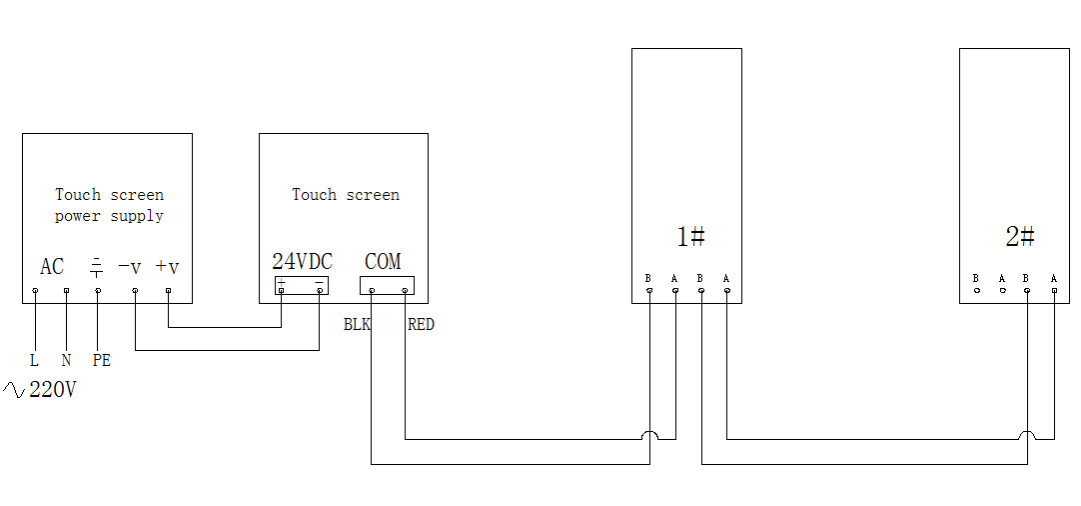

FFU Wiring diagram (Group control)

DSX FFU Introduction

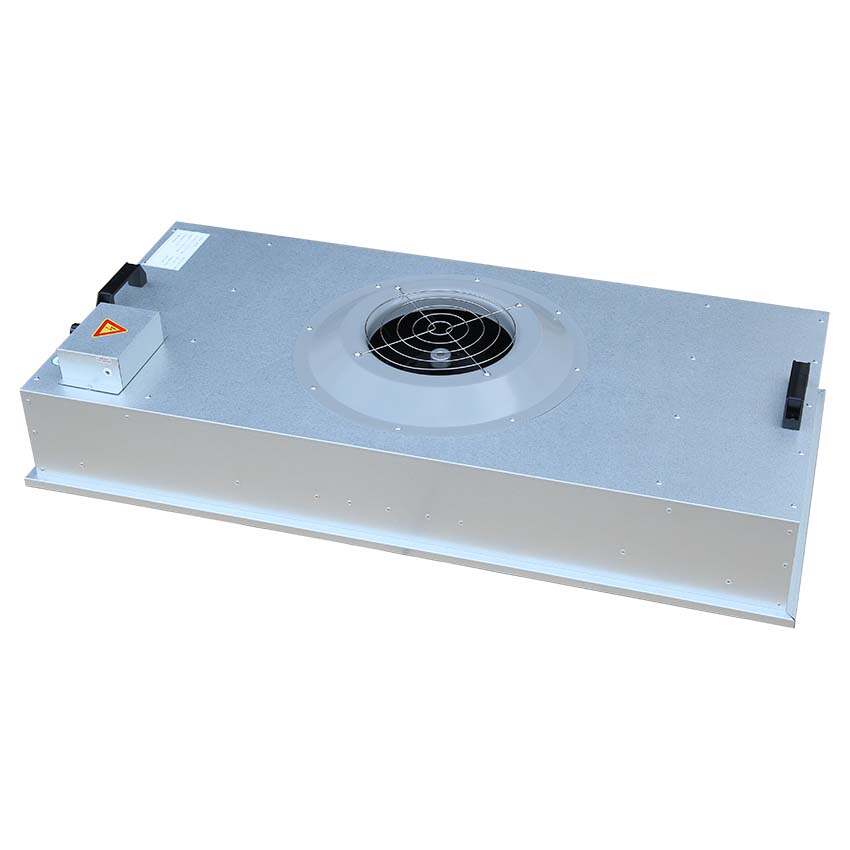

Versatile FFU Systems with Customizable Materials, Motors, and Controls

Materials for ontology that can be used as an option such as steel plate paint stainless steel 304, 316 Aluminum plate Optional several efficient AC/DC motorsIndividually controlled and centrally via a computer network. It can also be monitored remotely

Filters are made from fiberglass, PTFE, or are available using HEPA, ULPA filters of various levels of filtration.

Effective and quiet FFU Systems that are Space-Saving Design and a Stable Airflow.

DSX FFU uses an easy and light design which saves space and facilitates installation and maintenance.The particular design of the air intake and air conduit layout reduces noise, vibration, and noise production.

The internal diffuser plate provides an even air pressure distribution and stability of wind speed at the outlet.

Customizable FFU Systems with Energy-Efficient Motors

It is powered by a high-efficiency motor that can be adjusted to three speeds and low power consumption and low operating expenses (DC motors are also chosen to save energy). The motor was developed and manufactured by DSX and is able to be adjusted in accordance with the needs of the customer.

Versatile FFU Systems with Multiple Filter Options for Superior Filtration

Filter materials could be fiberglass, PTFE or optional HEPA and ULPA filtering systems with various filtering levels. Filter grade options include H13, U14 U15 and U16.

Perfect for special events

In addition to FFUs that are used in normal situations, we also offer FFUs that are specifically designed for industries that use lithium batteries, extremely thin FFUs for spaces with limited space, and explosion-proof FFUs. As a leading FFU producer, we are able to customize FFUs to suit various situations for our customers.

Make sure you are in a clean area

Each of DSX FFUs is assembled in cleanrooms to guarantee an extremely clean environment. Our FFUs strictly follow the strictest guidelines and adhere to cleanroom procedures throughout the production process. This strict approach ensures we can guarantee that the FFUs are clean of any contamination, which is essential to ensure optimal performance while maintaining clean working environments across a variety of applications.

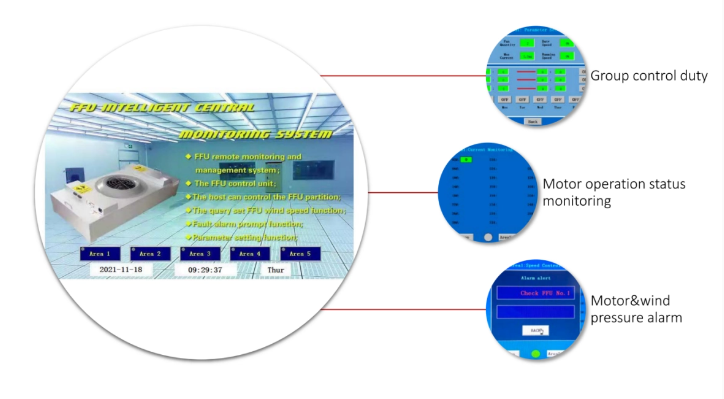

Customizable FFU Control System: Enhancing Efficiency and Performance

We have developed our FFU control system was developed and created by our own engineers, offering unparalleled flexibility and customization. With attention to particulars the control system we use offers an array of customizable options to satisfy specific customer needs. If it's creating the interface for control, altering rates of baud, or choosing the preferred option for display language Our control system is able to be customized to meet different communication styles and requirements of the customer. This flexibility allows for an easy integration into existing systems, and increases the overall effectiveness and efficiency for our FFUs.

Deshengxin FFU Regular parameters

| DESCRIPTION | Size(L*W*HMM) (Including HEPA) |

Air velocity (m3/h) |

Air flow (m/s) | Noise | Position of testing noise | Shell material | Power Supply | Rated power |

| Ultra thin FFU | 1175*575*180 | 1000 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.17kw |

| FFU575575 | 575*575*320 | 500 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.12kw |

| FFU615615 | 615*615*320 | 700 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.12kw |

| FFU915615 | 915*615*320 | 900 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.12kw |

| FFU1175575 | 1175*575*320 | 1000 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.12kw |

| FFU1175*1175 | 1175*1175*350 | 2000 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.18kw |

The size and other parameters can be customized according to the clients' demands.

1.FFU parameters(CE):

|

Model |

DSX-FFU01-02 |

DSX-FFU01-02 |

DSX-FFU01-03 |

DSX-FFU02-02 |

DSX-FFU02-04 |

|

FFU dimension (mm) |

575 x 575 x 210 |

1175 x 575 x 210 |

1175 x 575 x 270 |

1175 x 1175 x 270 |

1175x1175x210 |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

||||

|

Fan |

AC |

||||

|

Input |

230ACV/60HZ/1P |

||||

|

Speed (m/s) |

0.45~1 m/s±20% at high speed |

||||

|

Control type |

Manual |

||||

|

HEPA Height (mm) |

50 / 70 Optional |

||||

|

HEPA filter material |

Glass fibre |

||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||

|

Operating temperature |

10~40℃ |

||||

|

Structure type |

Split type |

||||

|

Installation mode |

Horizontal / Vertical |

||||

2. FFU parameters(Ultrathin type):

|

Model |

Ultrathin type |

|||

|

FFU dimension (mm) |

875X575X160 |

1350X460X160 |

1600X460X160 |

Other dimension |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

|||

|

Fan |

AC / EC |

|||

|

Input |

220ACV/50HZ/1P |

|||

|

Speed (m/s) |

0.45~0.7 m/s±20% at high speed |

|||

|

Control type |

Manual / RS485 |

|||

|

HEPA Height (mm) |

50 / 70 Optional |

|||

|

HEPA filter material |

Glass fibre |

|||

|

HEPA efficiency |

H13 / H14 /U15 |

|||

|

Operating temperature |

10~40℃ |

|||

|

Structure type |

Split type |

|||

|

Installation mode |

Horizontal / Vertical |

|||

3.FFU parameters(Conventional type):

|

Model |

Conventional type |

||||

|

FFU dimension (mm) |

575x575x230 |

765X510X230 |

1000X520X230 |

1175X575X230 |

Other |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

||||

|

Fan |

AC / EC |

||||

|

Input |

220ACV/50HZ/1P |

||||

|

Speed (m/s) |

0.45m/s±20% at high speed |

||||

|

Control type |

Manual / RS485 |

||||

|

HEPA Height (mm) |

50 / 70 Optional |

||||

|

HEPA filter material |

Glass fibre |

||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||

|

Operating temperature |

10~40℃ |

||||

|

Structure type |

Split type |

||||

|

Installation mode |

Horizontal / Vertical |

||||

4.FFU parameters(High speed type ):

|

Model |

High speed type |

|||

|

FFU dimension (mm) |

430X430X270 |

1175X575X270 |

1175X175X270 |

Other |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

|||

|

Fan |

AC / EC |

|||

|

Input |

220ACV/50HZ/1P |

|||

|

Speed (m/s) |

1m/s±20% at high speed |

|||

|

Control type |

Manual / RS485 |

|||

|

HEPA Height (mm) |

50 / 70 Optional |

|||

|

HEPA filter material |

Glass fibre |

|||

|

HEPA efficiency |

H13 / H14 /U15 |

|||

|

Operating temperature |

10~40℃ |

|||

|

Structure type |

Split type |

|||

|

Installation mode |

Horizontal / Vertical |

|||

5.FFU parameters(Special type ):

|

Model |

F-DA190X1-SUS304-400X400X100-F50H13 |

F-DA190X1-SUS304-430X430X120-F70H13 |

|

FFU dimension (mm) |

400 X 400 X 100 |

400 X 400 X 120 |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

|

|

Fan |

AC |

|

|

Input |

220ACV/50HZ/1P |

|

|

Speed (m/s) |

0.25m/s±20% at high speed |

|

|

Control type |

Manual |

|

|

HEPA Height (mm) |

50 / 70 Optional |

|

|

HEPA filter material |

Glass fibre |

|

|

HEPA efficiency |

H13 / H14 /U15 |

|

|

Operating temperature |

10~40℃ |

|

|

Structure type |

Split type |

|

|

Installation mode |

Horizontal / Vertical |

|

HEPA filter parameters

|

HEPA grade |

H13 |

H14 |

U15 |

|

HEPA eff. |

99.99%@0.3um |

99.995%@0.3um |

99.9995%@0.3um |

|

Material |

Glass fibre |

||

|

Frame material |

Aluminium alloy |

||

|

Net cover |

High quality steel baking paint (double-sided) |

||

|

Gasket |

High density synthetic rubber |

||

6.FFU parameters(3 speed type )

|

Model |

3 speed type FFU |

||||||

|

FFU dimension (mm) |

600X400 |

700X400 |

575X575 |

1175X575 |

1350X400 |

1470X400 |

Other |

|

FFU material |

Powder coated |

||||||

|

Fan |

AC |

||||||

|

Input |

220-230ACV/50HZ/1P |

||||||

|

Speed (m/s) |

0.45-1.0m/s Adjustable |

||||||

|

Control type |

Manual / RS485 |

||||||

|

HEPA Height (mm) |

50 / 70 / 90 Optional |

||||||

|

HEPA filter material |

Glass fibre |

||||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||||

|

Operating temperature |

10~40℃ |

||||||

|

Structure type |

Split type / Integrated |

||||||

|

Installation mode |

Horizontal / Vertical |

||||||

7.FFU parameters(3 speed room side replacement type ):

|

Model |

3 speed room side replacement typeFFU |

||||||

|

FFU dimension (mm) |

600X400 |

700X400 |

575X575 |

1175X575 |

1350X400 |

1470X400 |

Other(其他) |

|

FFU material |

Powder coated |

||||||

|

Fan |

AC |

||||||

|

Input |

220-230ACV/50HZ/1P |

||||||

|

Speed (m/s) |

0.45-1.0m/s Adjustable |

||||||

|

Control type |

Manual / RS485 |

||||||

|

HEPA Height (mm) |

50 / 70 / 90 Optional |

||||||

|

HEPA filter material |

Glass fibre |

||||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||||

|

Operating temperature |

10~40℃ |

||||||

|

Structure type |

Integrated |

||||||

|

Installation mode |

Horizontal / Vertical |

||||||

8.FFU parameters(EC energy saving type EC节能型):

|

Model |

EC energy saving type FFU |

||||||

|

FFU dimension (mm) |

600X400 |

700X400 |

575X575 |

1175X575 |

875X575 |

1010X610 |

Other(其他) |

|

FFU material |

Powder coated |

||||||

|

Fan |

EC |

||||||

|

Input |

220-230ACV/50HZ/1P |

||||||

|

Speed (m/s) |

0.45-1.0m/s Adjustable |

||||||

|

Control type |

RS485 |

||||||

|

HEPA Height (mm) |

50 / 70 / 90 Optional |

||||||

|

HEPA filter material |

Glass fibre |

||||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||||

|

Operating temperature |

10~40℃ |

||||||

|

Structure type |

Integrated |

||||||

|

Installation mode |

Horizontal / Vertical |

||||||