ʻAʻole hiki ke nele ka leka uila

ʻAʻole hiki ke nele ka ʻōlelo huna

Hapa ka hoʻopono leka uila

ʻAʻole hiki ke nele ka leka uila

Loaʻa ka leka uila

6-20 mau huapalapala (nā leka me nā helu wale nō)

ʻAʻole kūlike ka ʻōlelo huna

Hapa ka hoʻopono leka uila

ʻAʻole hiki ke nele ka leka uila

ʻAʻohe leka uila

6-20 mau huapalapala (nā leka me nā helu wale nō)

ʻAʻole kūlike ka ʻōlelo huna

Ulpa futch Unit (FFU)

ʻO ka hui kānana Fshengxin Ulpa Ua lako me ka hau hotra-haʻahaʻa haʻahaʻa (ulpa) kānana, hiki i kēia mau'āpana maikaʻi loa a me kaʻoi aku ka maikaʻi o ka maʻemaʻe. ʻO nā hiʻohiʻona koʻikoʻi a me nā pono: He Filternal Filternative kiʻekiʻe:ʻO ka puʻuwai o ka maʻi FFFXXIN ma ka 99.9999% ʻO kēia e hōʻoia i nā mea nui loa, e pili ana i nā mea nui o nā minuke, me nā baile, nā maʻi Kūpono no nā wahi koʻikoʻi He kūpono kūpono ia no nā noi ma nā hana, nā hoʻomaʻemaʻe hoʻomaʻemaʻe, e hana ana i nā hana semicongutor, a me nā hana'ē aʻe kahi i hiki ke hōʻole i nā hana a me nā hopena kūikawā. ʻO ka lele ikaika a me ka leo nui: e hoʻokaʻawaleʻia e kahi mea hana ec-ec-pono e hāʻawi ana i ka ffu a paʻa i ka lewa. Eia kekahi, e hana ana ka wae i ka pae haʻahaʻa haʻahaʻa haʻahaʻa, eʻae ana i nā limahana e hanaʻoluʻolu a weheʻoleʻia. Hoʻomaʻamaʻa maʻalahi a me ka hoʻonohonohoʻana:ʻO keʻano o ka huiʻana o ka maʻi Ke hoʻomau nei kēia i ka downtime a e hoʻomau i nā'āpana e noho ana i keʻano hana maikaʻi loa, ke kākoʻoʻana i nā hana maʻamau a me ka mālamaʻana i ke kiʻekiʻe o ka hoʻomaʻemaʻe. ʻO ka hana ikaika:ʻO ka hoʻohanaʻana o ka mana o ka mana o ka hana a me ka hoʻolālāʻana i ka hoʻolālāʻana i ka honua holoʻokoʻa e hāʻawi ai i kona olakino holoʻokoʻa holoʻokoʻa. ʻAʻole wale kēia i hōʻemi i nā kumukūʻai hana akā e loli pū me nā pahuhopu kūlohelohe o nā kaiāulu I ka hopena,ʻo ka Filter Fat Filter Unit ʻO kāna mau kiʻi kiʻi kiʻi kiʻekiʻe loa, ua hui pūʻia me ka hopena ikaika, maʻalahi ka maʻalahi, a hana i ka pono kūpono no ka hoʻomaʻemaʻeʻana a me ka maʻemaʻe. Inā he hana hana e hōʻike ana i ka noiʻi cutting-ceting, he hui lāʻau lapaʻau e hana ana i nā pae lapaʻau e hilinaʻi nei i nā pae kiʻekiʻe o ka hoʻomaʻemaʻeʻana a me ka palekana.

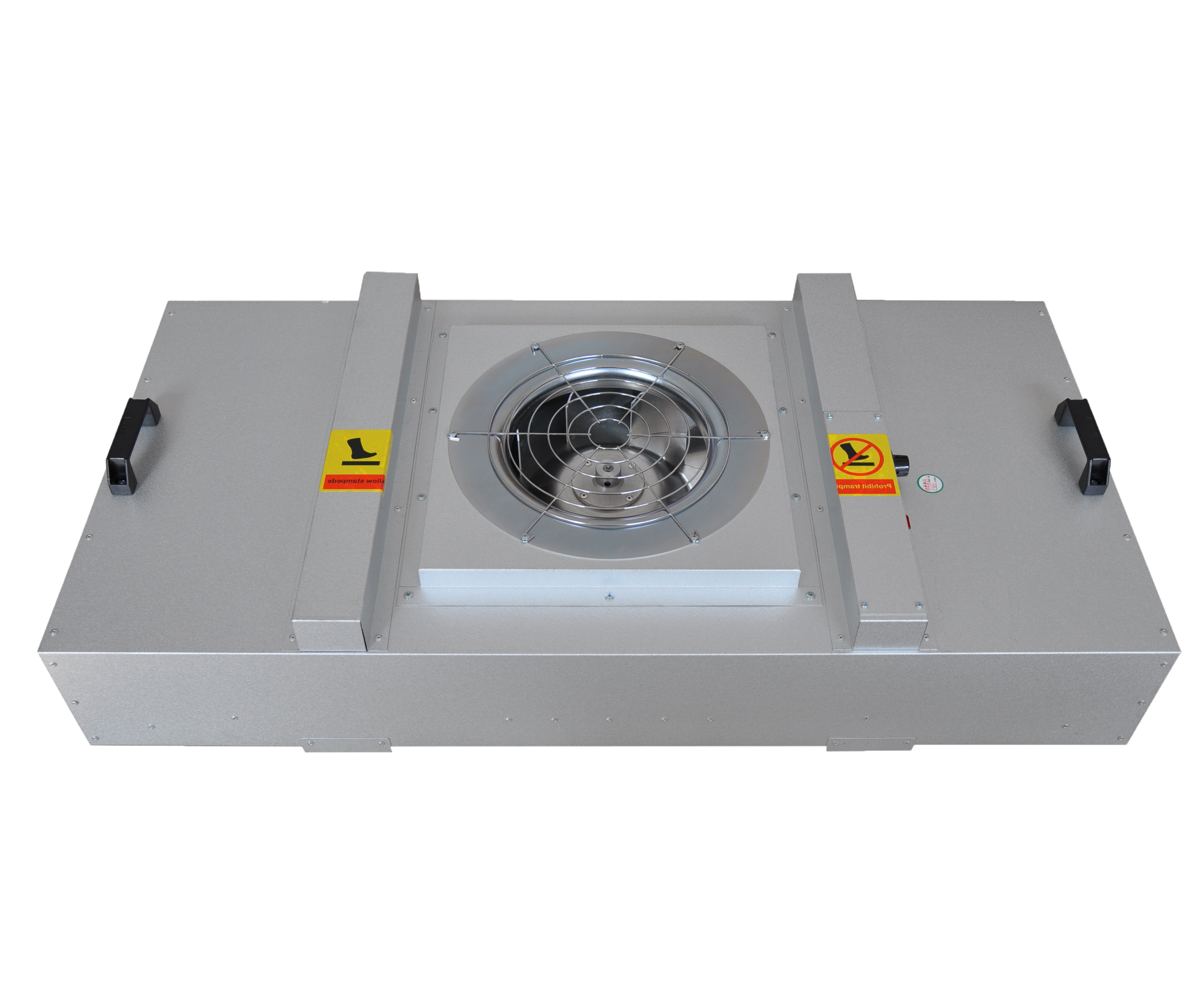

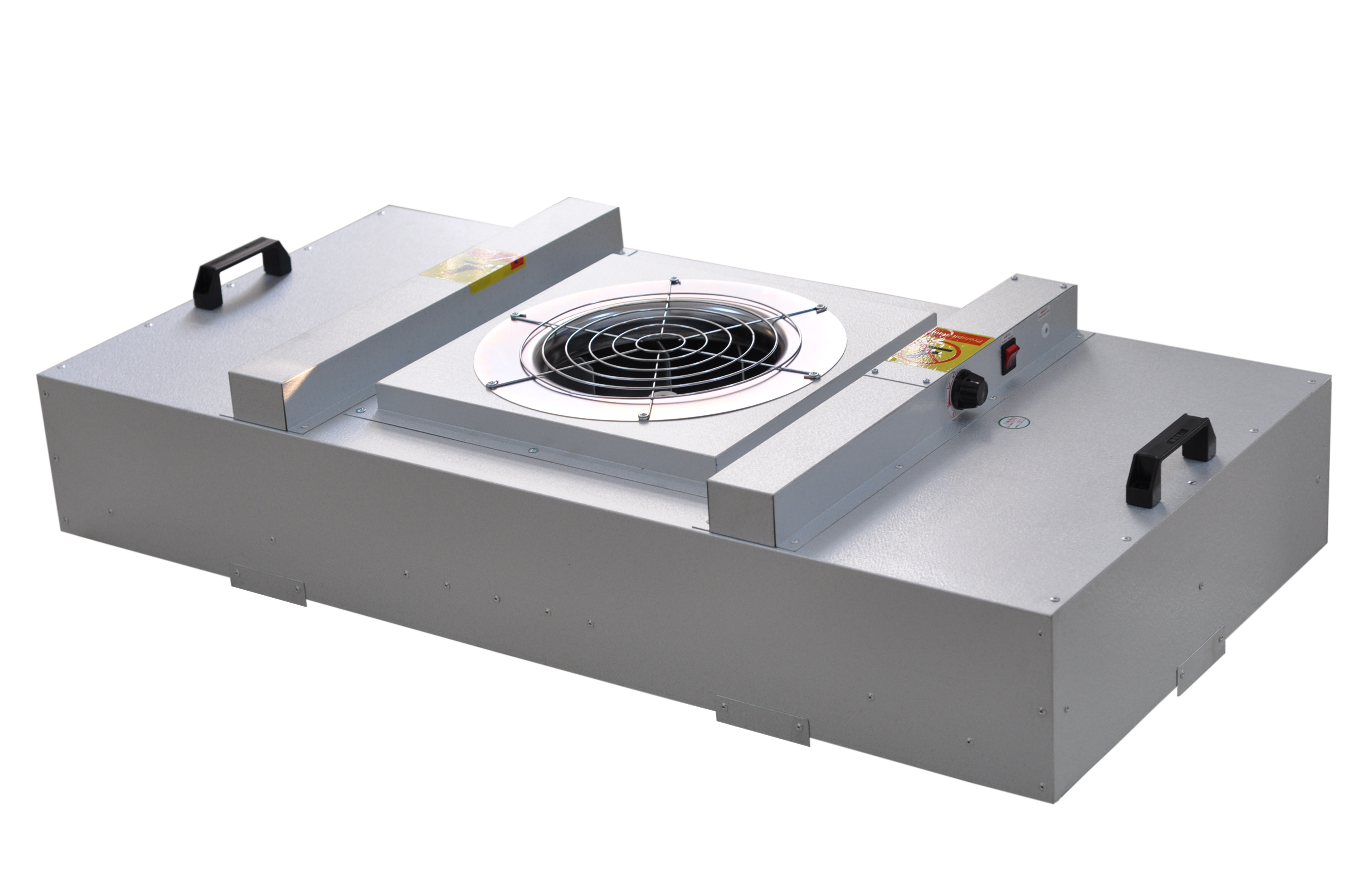

The Deshengxin ULPA Fan Filter Unit (FFU) is a cutting-edge solution designed to provide the ultimate level of air purification in environments where even the slightest contamination cannot be tolerated. Combining state-of-the-art technology with meticulous craftsmanship, this unit is specifically engineered to meet the rigorous demands of industries that require ultra-clean air, such as laboratories, pharmaceutical cleanrooms, and semiconductor manufacturing facilities.

Core Component: Ultra-Low Penetration Air (ULPA) Filter

At the heart of the Deshengxin ULPA FFU lies its exceptional filtration system, which utilizes an Ultra-Low Penetration Air (ULPA) filter. This advanced filter media is capable of removing particles as small as 0.12 microns in size with a filtration efficiency of up to 99.9999%. This level of performance far surpasses that of conventional HEPA filters, making the Deshengxin ULPA FFU the preferred choice for applications where extreme cleanliness is essential.

Superior Filtration Efficiency

The Deshengxin ULPA FFU is designed to eliminate a broad spectrum of contaminants from the air, including but not limited to dust, pollen, bacteria, viruses, smoke particles, and even submicron particles that are difficult to capture. This ensures that the air circulating in your critical environment is free from harmful impurities, protecting personnel health, preserving product quality, and maintaining the integrity of research or manufacturing processes.

Versatile Applications

With its exceptional filtration capabilities, the Deshengxin ULPA FFU is ideal for a wide range of applications, including:

Laboratories: Essential for biotechnology, microbiology, and pharmaceutical research, where even the smallest particles can compromise the accuracy of experiments and threaten the health of researchers.

Pharmaceutical Cleanrooms: Vital for the production of sterile drugs and medical devices, ensuring that products meet stringent quality control standards and remain free from contamination.

Semiconductor Manufacturing: Crucial for maintaining a particle-free environment during the fabrication of microchips and other electronic components, preventing defects and ensuring optimal performance.

Medical Device Manufacturing: Essential for the production of medical devices, such as implants and prosthetics, that must be free from contamination to ensure patient safety.

Cleanrooms in General Industry: Applicable in various industries requiring cleanroom environments, such as aerospace, automotive, and food processing.

Advanced Design Features

Energy-Efficient EC Motor: Powered by a highly efficient EC (Electronically Commutated) motor, the Deshengxin ULPA FFU consumes less energy while delivering strong and consistent airflow, reducing operating costs and contributing to environmental sustainability.

Low Noise Operation: The unit is designed to operate with minimal noise, creating a comfortable and undistracted work environment for personnel.

Easy Maintenance: With its modular design, filter replacement and maintenance are quick and straightforward, minimizing downtime and ensuring continuous operation.

Sturdy Construction: Made with high-quality materials and components, the Deshengxin ULPA FFU is built to last, withstanding the rigors of daily use in demanding environments.

In summary, the Deshengxin ULPA Fan Filter Unit (FFU) is a premium air purification solution that offers unparalleled filtration efficiency, versatility, and reliability. Its cutting-edge ULPA filter technology, combined with its energy-efficient design, low noise operation, and easy maintenance, make it the go-to choice for critical environments where cleanliness and purity are paramount. With the Deshengxin ULPA FFU, you can rest assured that your environment is protected from the smallest particles, ensuring the safety of personnel, the quality of your products, and the success of your operations.

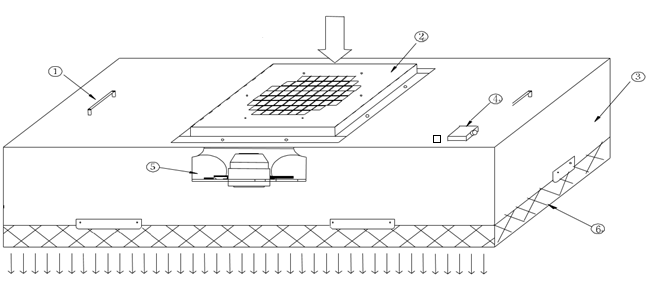

FFU Assembly diagram

|

1 |

|

5 |

Motor |

|

2 |

|

6 |

HEPA filter |

|

3 |

|

|

|

|

4 |

|

|

|

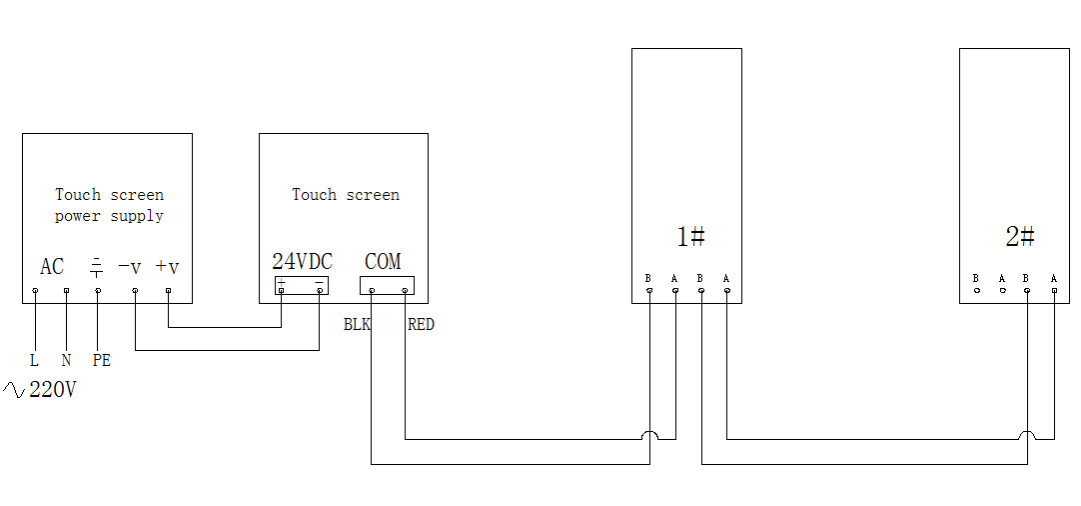

FFU Wiring diagram (Group control)

DSX FFU Introduction

Versatile FFU Systems with Customizable Materials, Motors, and Controls

Materials for ontology that can be used as an option such as steel plate paint stainless steel 304, 316 Aluminum plate Optional several efficient AC/DC motorsIndividually controlled and centrally via a computer network. It can also be monitored remotely

Filters are made from fiberglass, PTFE, or are available using HEPA, ULPA filters of various levels of filtration.

Effective and quiet FFU Systems that are Space-Saving Design and a Stable Airflow.

DSX FFU uses an easy and light design which saves space and facilitates installation and maintenance.The particular design of the air intake and air conduit layout reduces noise, vibration, and noise production.

The internal diffuser plate provides an even air pressure distribution and stability of wind speed at the outlet.

Customizable FFU Systems with Energy-Efficient Motors

It is powered by a high-efficiency motor that can be adjusted to three speeds and low power consumption and low operating expenses (DC motors are also chosen to save energy). The motor was developed and manufactured by DSX and is able to be adjusted in accordance with the needs of the customer.

Versatile FFU Systems with Multiple Filter Options for Superior Filtration

Filter materials could be fiberglass, PTFE or optional HEPA and ULPA filtering systems with various filtering levels. Filter grade options include H13, U14 U15 and U16.

Perfect for special events

In addition to FFUs that are used in normal situations, we also offer FFUs that are specifically designed for industries that use lithium batteries, extremely thin FFUs for spaces with limited space, and explosion-proof FFUs. As a leading FFU producer, we are able to customize FFUs to suit various situations for our customers.

Make sure you are in a clean area

Each of DSX FFUs is assembled in cleanrooms to guarantee an extremely clean environment. Our FFUs strictly follow the strictest guidelines and adhere to cleanroom procedures throughout the production process. This strict approach ensures we can guarantee that the FFUs are clean of any contamination, which is essential to ensure optimal performance while maintaining clean working environments across a variety of applications.

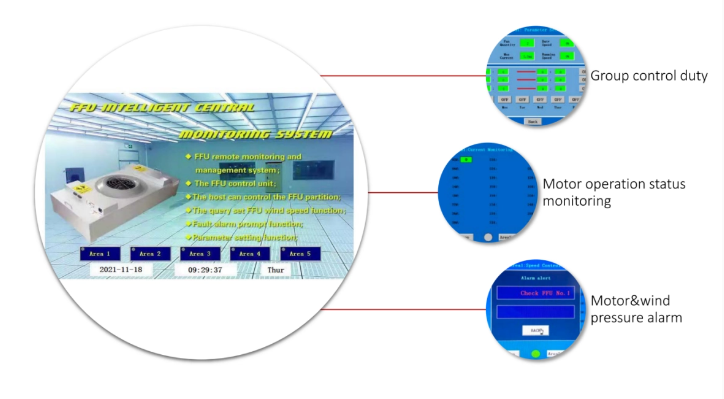

Customizable FFU Control System: Enhancing Efficiency and Performance

We have developed our FFU control system was developed and created by our own engineers, offering unparalleled flexibility and customization. With attention to particulars the control system we use offers an array of customizable options to satisfy specific customer needs. If it's creating the interface for control, altering rates of baud, or choosing the preferred option for display language Our control system is able to be customized to meet different communication styles and requirements of the customer. This flexibility allows for an easy integration into existing systems, and increases the overall effectiveness and efficiency for our FFUs.

Deshengxin FFU Regular parameters

| DESCRIPTION | Size(L*W*HMM) (Including HEPA) |

Air velocity (m3/h) |

Air flow (m/s) | Noise | Position of testing noise | Shell material | Power Supply | Rated power |

| Ultra thin FFU | 1175*575*180 | 1000 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.17kw |

| FFU575575 | 575*575*320 | 500 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.12kw |

| FFU615615 | 615*615*320 | 700 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.12kw |

| FFU915615 | 915*615*320 | 900 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.12kw |

| FFU1175575 | 1175*575*320 | 1000 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.12kw |

| FFU1175*1175 | 1175*1175*350 | 2000 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.18kw |

The size and other parameters can be customized according to the clients' demands.

1.FFU parameters(CE):

|

Model |

DSX-FFU01-02 |

DSX-FFU01-02 |

DSX-FFU01-03 |

DSX-FFU02-02 |

DSX-FFU02-04 |

|

FFU dimension (mm) |

575 x 575 x 210 |

1175 x 575 x 210 |

1175 x 575 x 270 |

1175 x 1175 x 270 |

1175x1175x210 |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

||||

|

Fan |

AC |

||||

|

Input |

230ACV/60HZ/1P |

||||

|

Speed (m/s) |

0.45~1 m/s±20% at high speed |

||||

|

Control type |

Manual |

||||

|

HEPA Height (mm) |

50 / 70 Optional |

||||

|

HEPA filter material |

Glass fibre |

||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||

|

Operating temperature |

10~40℃ |

||||

|

Structure type |

Split type |

||||

|

Installation mode |

Horizontal / Vertical |

||||

2. FFU parameters(Ultrathin type):

|

Model |

Ultrathin type |

|||

|

FFU dimension (mm) |

875X575X160 |

1350X460X160 |

1600X460X160 |

Other dimension |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

|||

|

Fan |

AC / EC |

|||

|

Input |

220ACV/50HZ/1P |

|||

|

Speed (m/s) |

0.45~0.7 m/s±20% at high speed |

|||

|

Control type |

Manual / RS485 |

|||

|

HEPA Height (mm) |

50 / 70 Optional |

|||

|

HEPA filter material |

Glass fibre |

|||

|

HEPA efficiency |

H13 / H14 /U15 |

|||

|

Operating temperature |

10~40℃ |

|||

|

Structure type |

Split type |

|||

|

Installation mode |

Horizontal / Vertical |

|||

3.FFU parameters(Conventional type):

|

Model |

Conventional type |

||||

|

FFU dimension (mm) |

575x575x230 |

765X510X230 |

1000X520X230 |

1175X575X230 |

Other |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

||||

|

Fan |

AC / EC |

||||

|

Input |

220ACV/50HZ/1P |

||||

|

Speed (m/s) |

0.45m/s±20% at high speed |

||||

|

Control type |

Manual / RS485 |

||||

|

HEPA Height (mm) |

50 / 70 Optional |

||||

|

HEPA filter material |

Glass fibre |

||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||

|

Operating temperature |

10~40℃ |

||||

|

Structure type |

Split type |

||||

|

Installation mode |

Horizontal / Vertical |

||||

4.FFU parameters(High speed type ):

|

Model |

High speed type |

|||

|

FFU dimension (mm) |

430X430X270 |

1175X575X270 |

1175X175X270 |

Other |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

|||

|

Fan |

AC / EC |

|||

|

Input |

220ACV/50HZ/1P |

|||

|

Speed (m/s) |

1m/s±20% at high speed |

|||

|

Control type |

Manual / RS485 |

|||

|

HEPA Height (mm) |

50 / 70 Optional |

|||

|

HEPA filter material |

Glass fibre |

|||

|

HEPA efficiency |

H13 / H14 /U15 |

|||

|

Operating temperature |

10~40℃ |

|||

|

Structure type |

Split type |

|||

|

Installation mode |

Horizontal / Vertical |

|||

5.FFU parameters(Special type ):

|

Model |

F-DA190X1-SUS304-400X400X100-F50H13 |

F-DA190X1-SUS304-430X430X120-F70H13 |

|

FFU dimension (mm) |

400 X 400 X 100 |

400 X 400 X 120 |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

|

|

Fan |

AC |

|

|

Input |

220ACV/50HZ/1P |

|

|

Speed (m/s) |

0.25m/s±20% at high speed |

|

|

Control type |

Manual |

|

|

HEPA Height (mm) |

50 / 70 Optional |

|

|

HEPA filter material |

Glass fibre |

|

|

HEPA efficiency |

H13 / H14 /U15 |

|

|

Operating temperature |

10~40℃ |

|

|

Structure type |

Split type |

|

|

Installation mode |

Horizontal / Vertical |

|

HEPA filter parameters

|

HEPA grade |

H13 |

H14 |

U15 |

|

HEPA eff. |

99.99%@0.3um |

99.995%@0.3um |

99.9995%@0.3um |

|

Material |

Glass fibre |

||

|

Frame material |

Aluminium alloy |

||

|

Net cover |

High quality steel baking paint (double-sided) |

||

|

Gasket |

High density synthetic rubber |

||

6.FFU parameters(3 speed type )

|

Model |

3 speed type FFU |

||||||

|

FFU dimension (mm) |

600X400 |

700X400 |

575X575 |

1175X575 |

1350X400 |

1470X400 |

Other |

|

FFU material |

Powder coated |

||||||

|

Fan |

AC |

||||||

|

Input |

220-230ACV/50HZ/1P |

||||||

|

Speed (m/s) |

0.45-1.0m/s Adjustable |

||||||

|

Control type |

Manual / RS485 |

||||||

|

HEPA Height (mm) |

50 / 70 / 90 Optional |

||||||

|

HEPA filter material |

Glass fibre |

||||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||||

|

Operating temperature |

10~40℃ |

||||||

|

Structure type |

Split type / Integrated |

||||||

|

Installation mode |

Horizontal / Vertical |

||||||

7.FFU parameters(3 speed room side replacement type ):

|

Model |

3 speed room side replacement typeFFU |

||||||

|

FFU dimension (mm) |

600X400 |

700X400 |

575X575 |

1175X575 |

1350X400 |

1470X400 |

Other(其他) |

|

FFU material |

Powder coated |

||||||

|

Fan |

AC |

||||||

|

Input |

220-230ACV/50HZ/1P |

||||||

|

Speed (m/s) |

0.45-1.0m/s Adjustable |

||||||

|

Control type |

Manual / RS485 |

||||||

|

HEPA Height (mm) |

50 / 70 / 90 Optional |

||||||

|

HEPA filter material |

Glass fibre |

||||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||||

|

Operating temperature |

10~40℃ |

||||||

|

Structure type |

Integrated |

||||||

|

Installation mode |

Horizontal / Vertical |

||||||

8.FFU parameters(EC energy saving type EC节能型):

|

Model |

EC energy saving type FFU |

||||||

|

FFU dimension (mm) |

600X400 |

700X400 |

575X575 |

1175X575 |

875X575 |

1010X610 |

Other(其他) |

|

FFU material |

Powder coated |

||||||

|

Fan |

EC |

||||||

|

Input |

220-230ACV/50HZ/1P |

||||||

|

Speed (m/s) |

0.45-1.0m/s Adjustable |

||||||

|

Control type |

RS485 |

||||||

|

HEPA Height (mm) |

50 / 70 / 90 Optional |

||||||

|

HEPA filter material |

Glass fibre |

||||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||||

|

Operating temperature |

10~40℃ |

||||||

|

Structure type |

Integrated |

||||||

|

Installation mode |

Horizontal / Vertical |

||||||